- Category:3.PVC Shrink Film

- Product Description:

Yancheng Kingbull Materials Technology Co.,Ltd. was established in 2009, and the state key high-tech enterprise is located inYanCheng,Jiangsu,China. we are a professional large-scale manufacture of Water based glue , themal lamination film,packing film.The product rangecovers the mainland, North America, Yemen, Dubai,Vietnam,Syria,Colombia,Saudi Arabia Thailand,Colombia,Philippines ,Mexico,UZ,Australia,Mongoliaand other countries.

YANCHENG KINGBULL MATERIALS TECHNOLOGY CO.,LTD

Contact:Mr Peter

Address:NO.288 JIeFang Road,Zhongnan Century City YanCheng City,JIangSu Province ,China Postcode:224001.

Tel:+86 515 88171436 Fax:+86 515 88130612MT:8613851082103 Wechat&What's App:+8613851082103

Email:chinabestcorp@vip.163.com or info@king-bull.com

Product details

Packaging Film Usage And PVC Material Heat Shrink Film

PVC SHRINK FILM(Polyvinyl Chloride)is the most common shrink film type in the market now. Printing grade pvc shrink film is one

kind of economic packaging material with good quality which is widely used in all kinds of packaging industry,such as

food,beverage and other daily use.

PVC is a high density film that shrinks at low temperature ranges.The most commonly used shrink sleeve material for the market.It

has excellent shrinkage rates,clarity,print quality,and a wide range of both shrink temperatures and shrink ratios.PVC also has

high impact strength for extra weather resistance.This scuff resistant shrink sleeve material has the lowest cost.

Specification

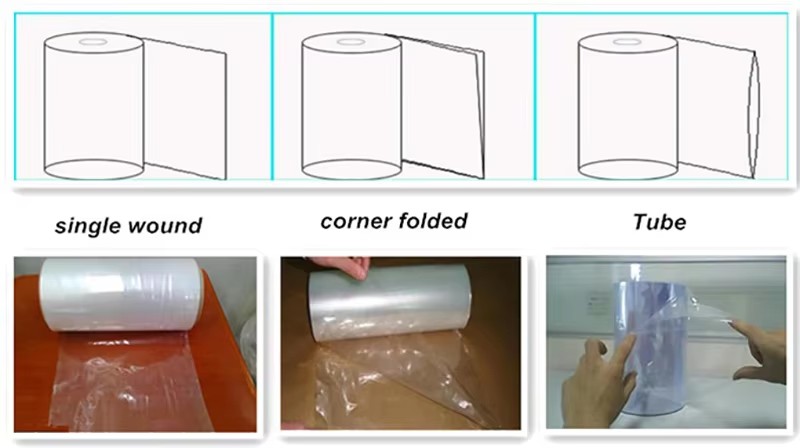

Packing & Delivery

- Previous: Custom Clear POF/PVC Plastic Heat Shrink Wrap Bag for Packing

- Next:

WeChat QR code

WeChat QR code What's App

What's App